Engineering Dept. embraces new technology

February 7, 2021

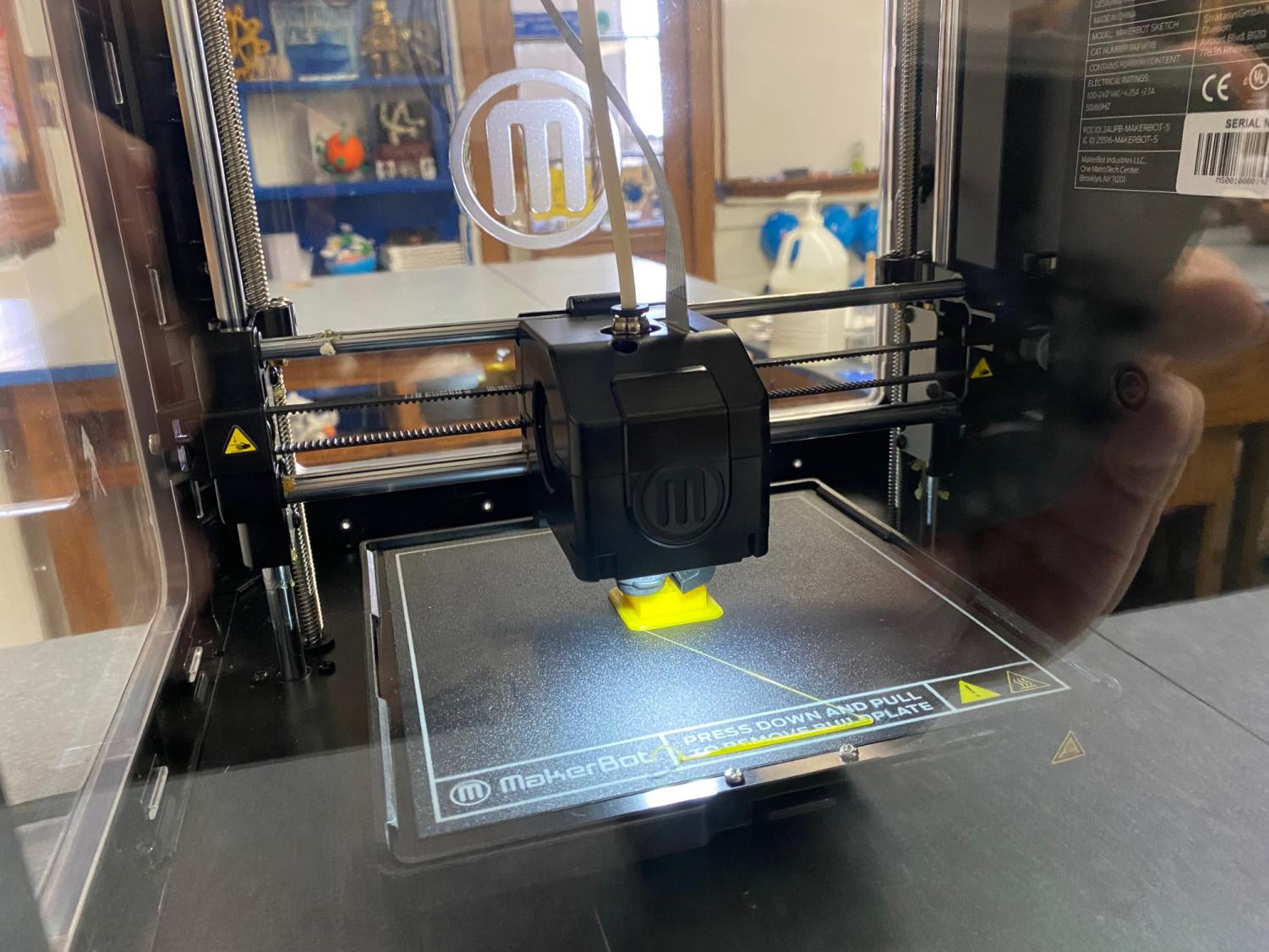

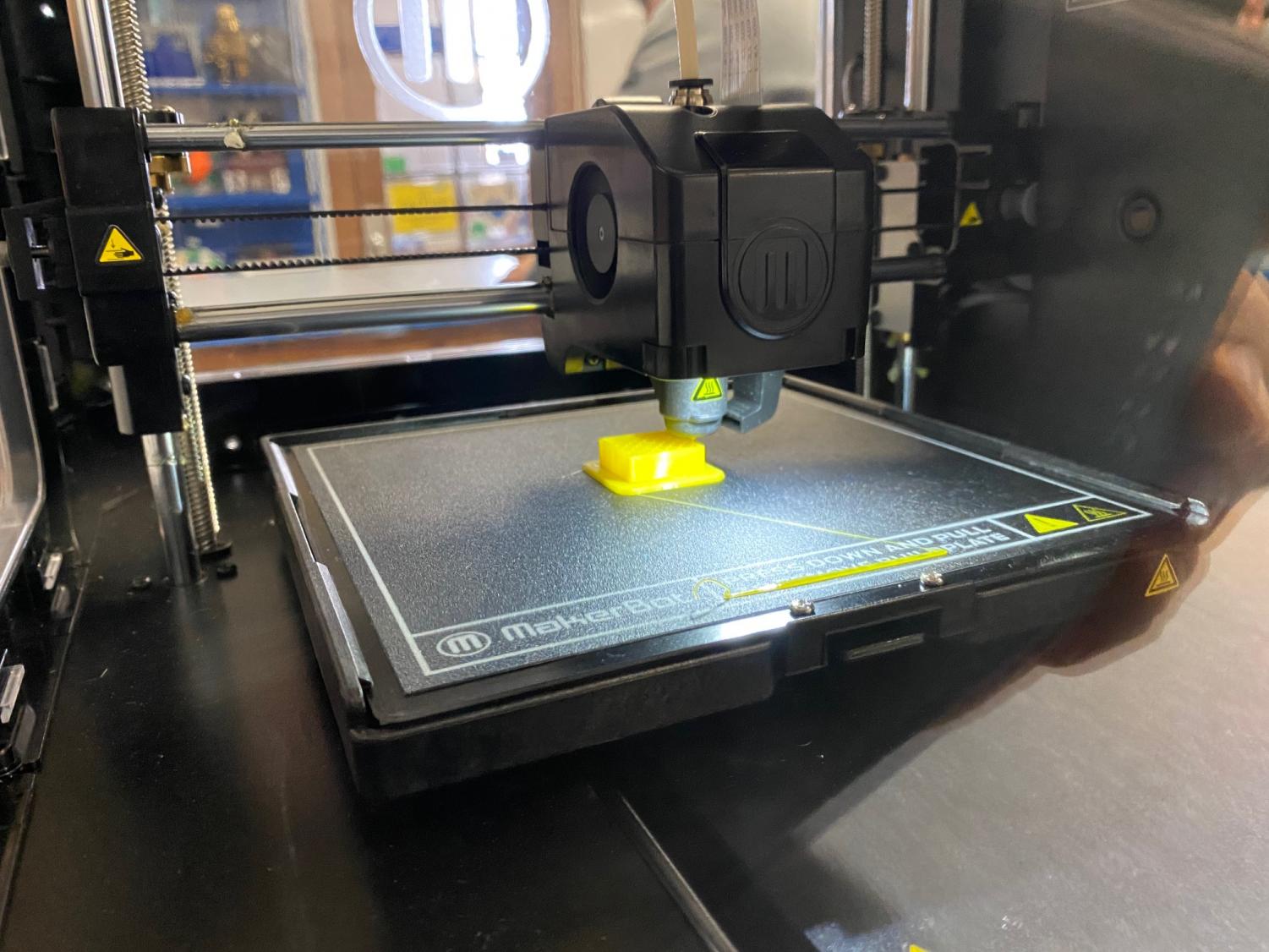

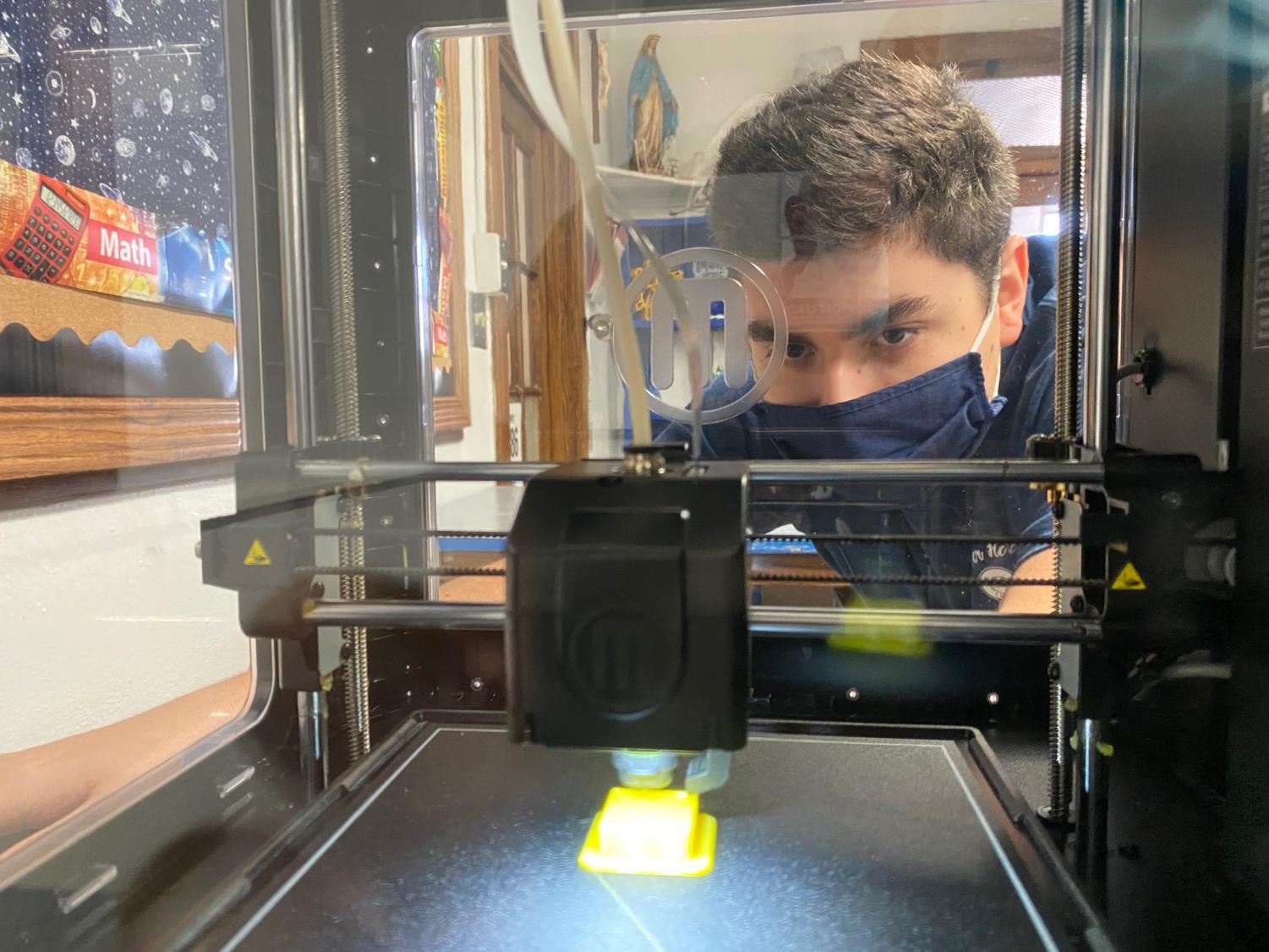

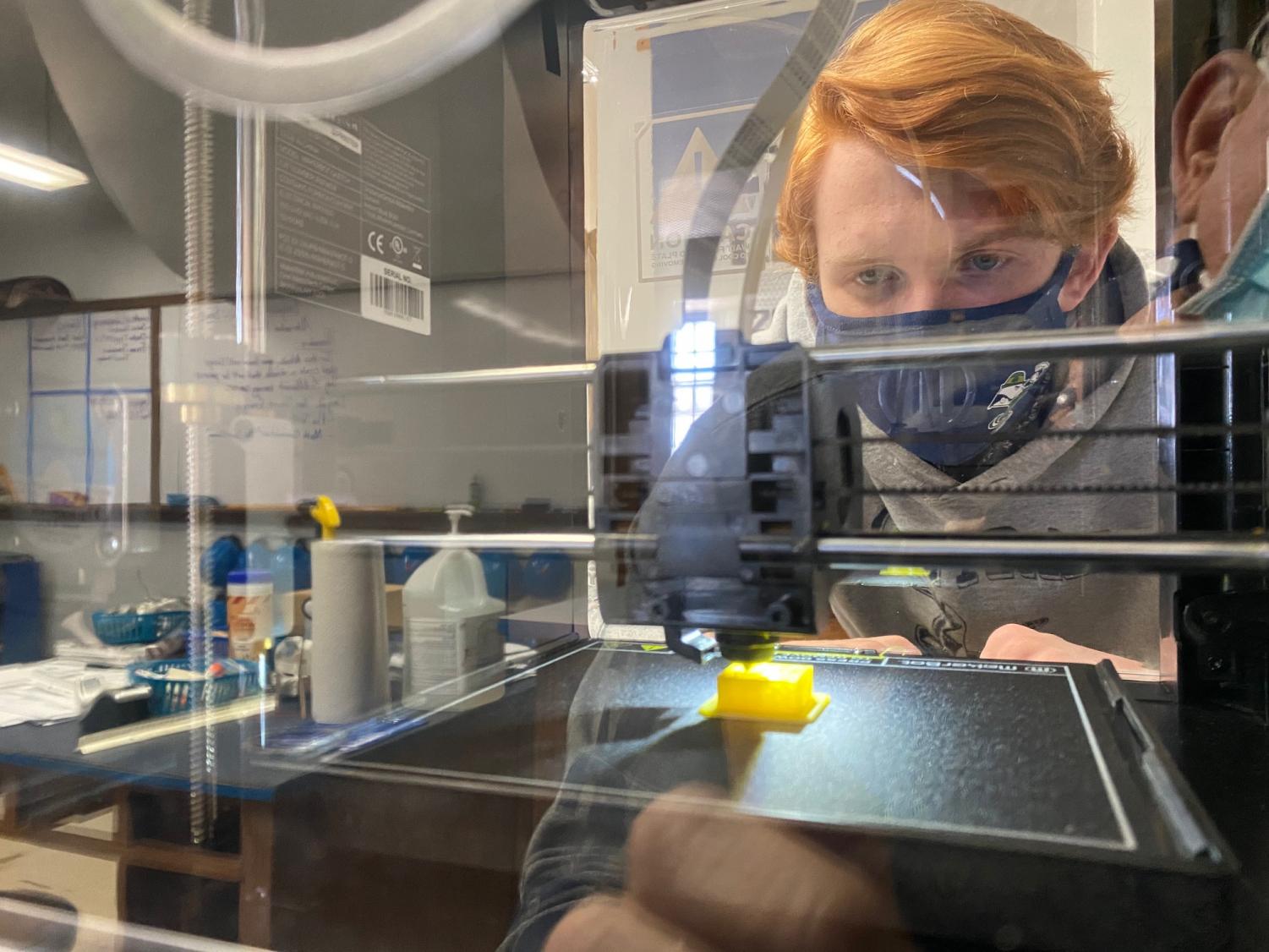

The Engineering Department at the school has been using some innovative new machines in their classes and clubs. Engineering and robotics classes specifically have first-hand access to them as apart of their lessons.

Sharon Jarmon, the Engineering and Robotics teacher, and S.T.E.M. Coordinator, talks about the importance and purpose these new machines will be on campus. “In the efforts of fostering today’s students, tomorrow’s workforce, Student will gain industry knowledge which will encourage inventors & enhancing collaborative effort through brain storming and working together to solve real – world problems,” she says. She continues, “All my engineering & robotics classes will use and have access to the machine which is apart of our lessons. 2 teachers including myself along with 10 students have an opportunity to train and obtain a certification in MarkBot 3D printing.”

She explains the brands and software used in more detail. MarkBot 3D printing, she says is, “3D printing relies heavily on designers who can take a product idea and translate it into something that can feasibly be brought to life.”

For their software, called Solidworks, she says it is, “3D Computer- aided Design (CAD) Modeling: Is used in my Engineering Design & Graphics Dual Credit classes which allows my students to have the skills and expertise to convert product designs into digital blueprints that 3D printers need.” She continues, “Also, at the end of the semester the Engineering Dual Credit students will take the SOLIDWORKS Associate exam (CSWA) which is an in-demand industry professional certification that covers 3D modeling, design concepts, and sustainable design.”

Jarmon shares her own thoughts on the innovative technology: “My thoughts are simple. I’m glad to use the machines & software as a fun resource to enhance my curriculum and lessons. Easy accessibility to hands on learning which will help unlock our students creative potential. CAD & 3D printing is becoming the manufacturing device of the future. Therefore, getting our students to learn the basics of using 3D is an opportunity to prepare for the future of production. I’m very excited to be able to facilitate the learning and development of Central Catholic’s future leaders.”

Jarmon also says that the machines are located in room 275, also known as the Engineering Classroom. She also says the machines are open to staff and students.